Injector pulse is a critical aspect of the proper functioning of an engine. Without it, fuel will not be properly delivered to combustion chambers, and your vehicle will not start or run efficiently. Checking the injector pulse is a relatively easy task that can be accomplished in a few steps with basic tools and minimal mechanical knowledge. This article will provide an in-depth, step-by-step guide to checking injector pulse, including what tools are required, how to locate the injectors, what readings indicate proper functioning, and what can happen if the injector pulses are not operating correctly. This information lets you quickly identify issues and take corrective action before major engine problems occur.

What Is the Purpose of Checking an Injector Pulse?

The purpose of checking an injector pulse is to ensure that the fuel injector operates as it should. An injector pulse is an electric signal sent from the car’s ECU to its fuel injectors, which signals them to open and close at a specific time and for a specific duration. It allows for precise control over how much fuel enters the combustion chamber, thus affecting power output and fuel efficiency. Checking an injector pulse can help diagnose any issues with this system, such as clogged or dirty injectors, faulty wiring or electronics, low-pressure pumps, or even a faulty ECU itself. A diagnostic test on the injection system can identify potential problems before they cause more serious damage to other vehicle parts.

Tools Needed for Injector Pulse Testing

How to Check an Injector Pulse

Before beginning the injector pulse testing procedure, it is crucial to ensure the engine is shut off and the ignition key is removed. Once this is done, the following steps can be taken to check the injector pulse:

-

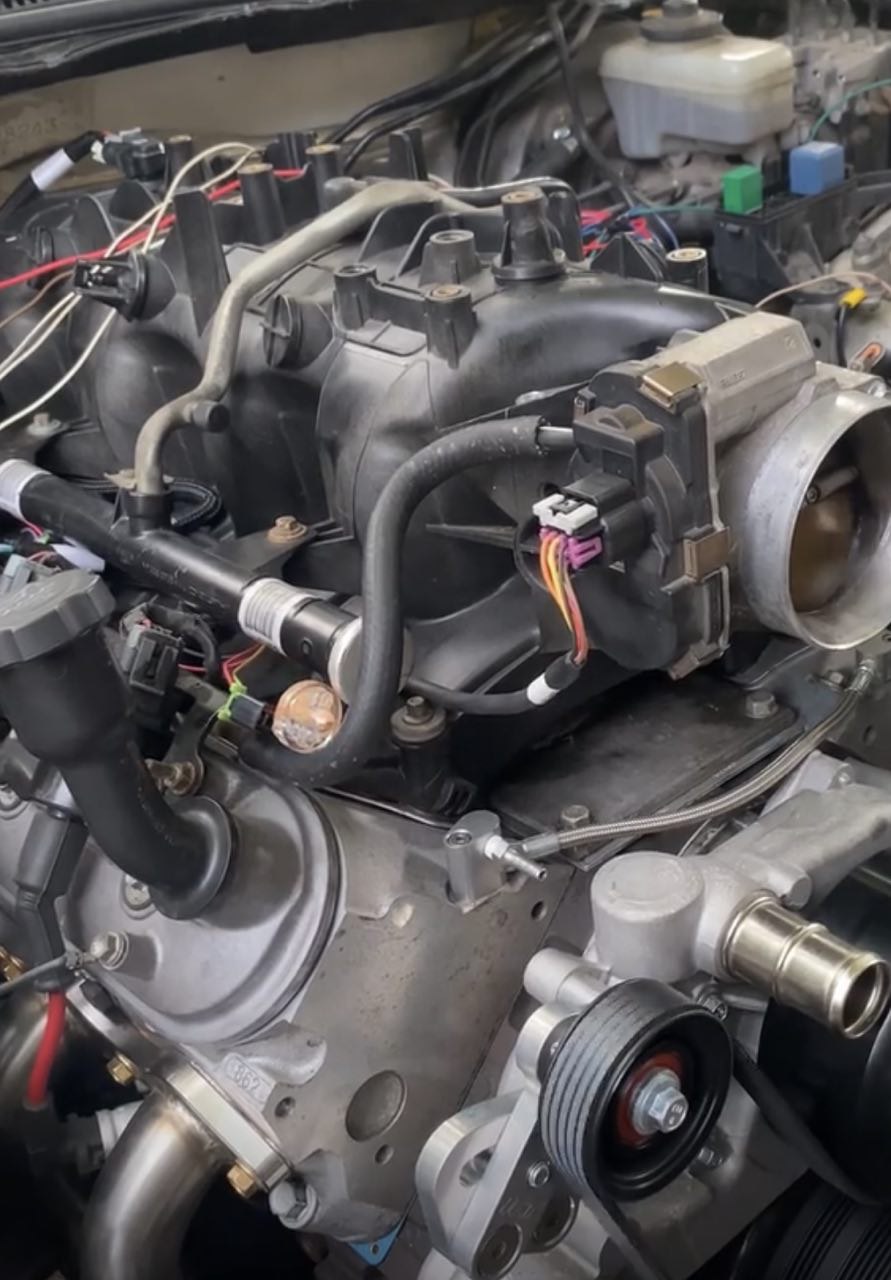

Locate the fuel injectors on your vehicle. Depending on your engine type, it can usually be found near or on the block.

-

Using a digital multimeter, test the wiring harness of each injector for electrical signals. The readings should indicate a voltage of around 12V when tested. If no voltage is present, look for damages in the wiring harness or faulty connections between components to find out what might be causing this issue.

-

Connect a 12V test light between two consecutive fuel injectors and turn on the vehicle’s ignition (but not its engine). The test light should illuminate with each electrical signal sent from the ECU to open and close an injector valve, indicating the proper functioning of both components.

-

Clean the fuel injectors with fuel injector cleaner to remove any dirt or debris that might be causing problems in the system.

-

Test the injector pulse again with the digital multimeter and 12V test light to see if any improvements have been made. If not, further diagnostics will be needed to identify the source of any faults.

Conclusion

Checking the injector pulse in your Jeep is a relatively simple task that can save you from replacing expensive components. Using a digital multimeter and 12V test light, you can quickly identify electrical signals sent from the ECU to each fuel injector. This process will also help determine if any dirt or blockage may be causing an issue with the proper functioning of the injectors. Be sure to take all necessary safety precautions when working around engine components, and always keep fuel injector cleaner on hand for maintenance and cleaning of dirty or clogged injectors.

Add Comment