If you own a Jeep, you may have come across the issue of an oil dipstick that has broken off in its tube. It can be a tricky problem to solve, as it requires specialized tools and knowledge to successfully remove the broken piece and replace it with a new one. The purpose of this article is to provide step-by-step instructions for fixing your Jeep’s oil dipstick when it breaks off.

Signs of an Oil Dipstick Problem

Signs of an oil dipstick problem can manifest in various ways. One indication is having trouble or resistance when inserting or removing the dipstick, which could be caused by a misalignment or blockage in the dipstick tube or a damaged dipstick itself. Another sign is consistently obtaining inaccurate oil level readings, whether they are unusually high or low. This could be a result of a bent or broken dipstick or a faulty dipstick tube. Oil leaks around the dipstick tube or on the dipstick can also indicate a problem, often caused by a damaged or worn-out O-ring or seal. Additionally, if you notice excessive oil consumption or burning, or if you observe blue smoke coming from the exhaust, it may suggest a dipstick problem that leads to improper oil levels and potential engine damage. Lastly, visually inspecting the dipstick for any damage, such as a cracked or broken handle or illegible markings, can also reveal a dipstick issue.

Tools and Materials Needed for Repair

- A socket wrench set with various sizes of sockets

- An adjustable pipe wrench

- Pliers with needle-nose attachments

- A small flathead screwdriver

- A pair of channel locks or vise grips

- An automotive penetrating oil, such as WD-40 or PB Blaster

You will also need a new replacement oil dipstick for the Jeep, which you can find at most auto parts stores.

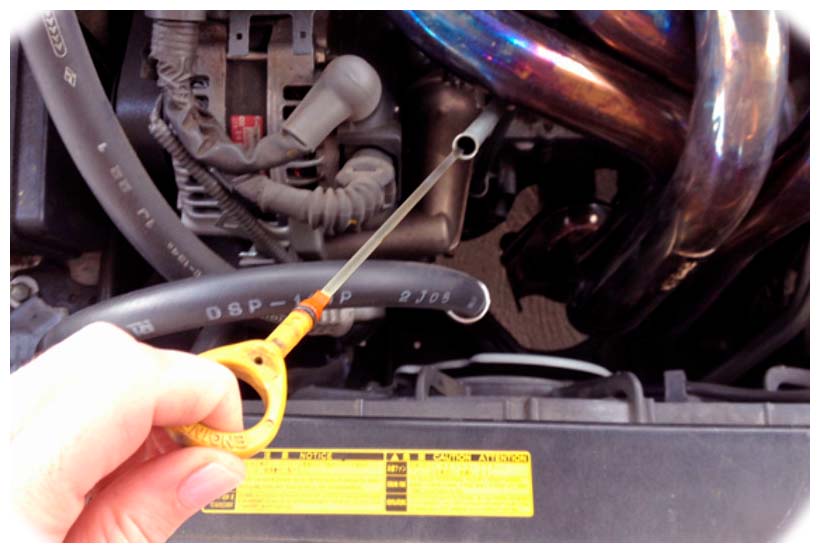

Removing the Damaged Oil Dipstick

Start by inspecting the interior of the dipstick tube to see if any pieces of the broken dipstick remain inside. If there are any large remaining fragments, use a pair of needle-nose pliers to grasp it and carefully pull it out. If necessary, use a small flathead screwdriver to wedge and assist in removing larger pieces. For any remaining smaller particles or debris in the tube, apply some penetrating oil and let it soak for 15 minutes before attempting further removal with your pliers. Once all fragments have been successfully extracted, wipe out any remaining residue from within the tube with a clean cloth.

Replacing the New Oil Dipstick

Before inserting your new oil dipstick into its tube, ensure that both surfaces are completely dry by wiping them down with a clean cloth. Place lubricant such as silicone grease on both ends of the dipstick, as well as on the inside of its tube. Insert the dipstick into the tube and rotate it several times to evenly spread the lubricant. Next, use your socket wrench to tighten two nuts that secure either end of the dipstick in place – these must be tightened securely so that there is no possibility of leakage. Lastly, top off your engine’s oil level to ensure the proper functioning and check for any signs of leaks or malfunctioning components.

Tips for Preventing Further Damage

The best way to prevent further damage from occurring is by properly taking care of your Jeep’s oil level and dipstick. Make sure you regularly check your oil level with a clean, dry cloth before each drive and replace any dirty or damaged parts when necessary. Additionally, try not to overfill or underfill your engine’s oil as this can cause excessive wear on internal parts and lead to damage over time. Lastly, avoid using harsh chemicals on the exterior of the dipstick since they can corrode it and create a weak point in its construction. In the same vein, it’s also beneficial to know about the best oil for Jeep. Using quality oil that’s right for your vehicle can significantly enhance its performance and lifespan.

Conclusion

Fixing an oil dipstick that has broken off in a Jeep’s tube can be a tricky process but with the right tools and knowledge, it is possible to successfully remove the broken piece and replace it with a new one. Make sure you pay close attention to the signs of a dipstick problem so that you can act immediately if you ever experience any issues. With proper care, you can prevent further damage from occurring and keep your Jeep running smoothly for years to come.

Add Comment