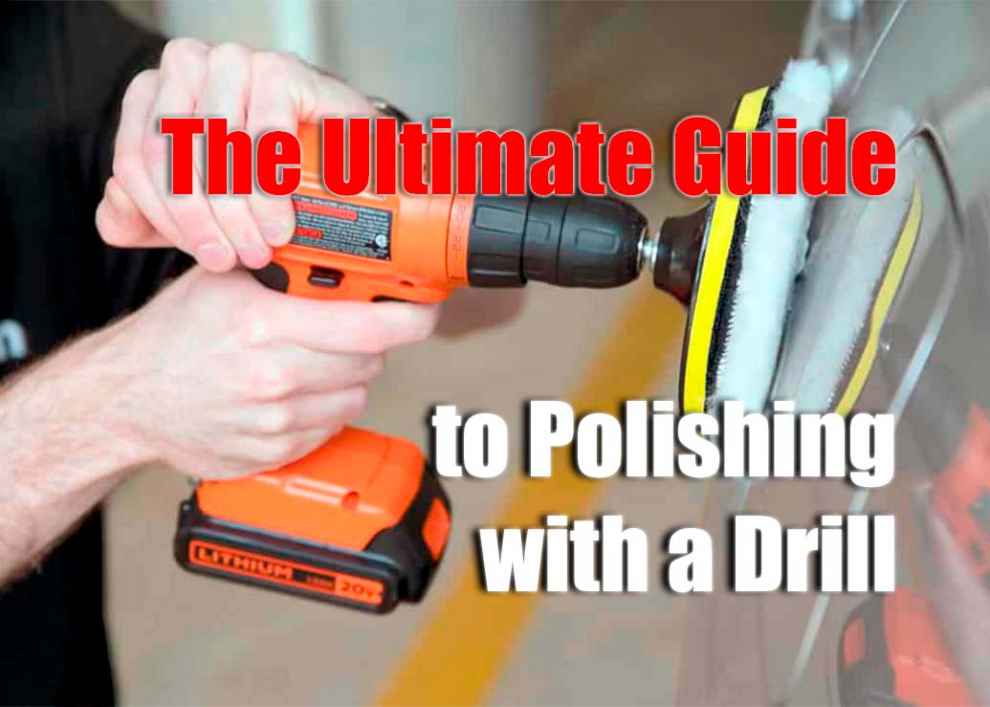

In the world of automotive care and maintenance, one of the most rewarding tasks is polishing your vehicle to its maximum shine. The gleaming finish not only improves the look but also provides an additional protective barrier against the tough elements of the environment. Now, imagine owning a robust vehicle like a Jeep – known for its adventurous rides and off-road escapades. Maintaining its beauty can often be challenging, particularly for individuals who are inexperienced or not well-versed in the procedure. This article serves as a guide to polishing with a drill, making it an essential read for every Jeep owner out there. It’s going to walk you through all the necessary steps, from choosing the right drill and polishing pads to detailing various techniques for achieving that perfect lustrous finish on your rugged beast. Whether you’re an experienced motorhead or just starting out on your car care journey, this guide will prove valuable in maintaining your Jeep’s looks while enhancing its longevity.

Essential Tools and Materials for Drill Polishing

For effective drill polishing of your Jeep, having the right tools and materials is crucial. Firstly, you need a high-quality drill. Either a corded or cordless model will work, but ensure it has variable speed control for greater precision. Next, invest in a range of polishing pads. Foam pads are ideal for applying polish, while wool or microfiber pads are better for buffing out scratches and achieving a high gloss finish. Polishing compounds are also essential; select a range that caters to different stages of polishing, from heavy cutting compounds to fine polishes. Don’t forget a backing plate to attach the pads to your drill. It’s essential to wear protective equipment like gloves and safety glasses to safeguard yourself throughout the procedure. Lastly, have microfiber towels on hand for wiping down the surface after polishing. Gathering these tools and materials ensures you’re well-prepared to achieve that showroom shine on your Jeep.

Preparing Your Jeep for Polishing

The preparation phase is a critical step before you start polishing your Jeep. Start with a comprehensive cleaning of the vehicle to eliminate all dirt, grime, and any accumulated debris. Pay special attention to any mud or residue that might have accumulated from off-road adventures. After washing, dry the vehicle completely to avoid water spots. Next, inspect the surface for any scratches or imperfections that might need pre-treatment before polishing. It’s recommended to use a clay bar on the Jeep’s surface to remove any fine particles and achieve a smooth base for polishing. If there are any significant scratches or paint imperfections, consider using a scratch remover or a mild abrasive compound before the actual polishing. This preparation not only ensures a cleaner surface for polishing but also enhances the final results, making your Jeep look as good as new. Also read about the Best Cleaner for Jeep Soft Top to maintain the top of your Jeep in pristine condition.

Polishing with a Drill: Step-by-step Guide

- Attach the selected polishing pad securely to the drill’s backing plate.

- Apply a small quantity of polishing compound onto the pad.

- Start the drill at a low speed to prevent compound splatter and maintain control.

- Press the pad lightly against the Jeep’s surface, moving in steady, overlapping circles.

- Ensure each area of the Jeep receives even polishing for a consistent finish.

- Increase the drill speed gradually for more intensive polishing, while carefully managing the pressure applied.

- Pause regularly to wipe away residue with a microfiber cloth, assessing your progress.

- For intricate areas, consider using smaller pads for better maneuverability and precision.

- End the process with a finer polish or a glaze to enhance the overall shine and brilliance.

This list provides a structured methodology to achieve a thorough and even polish on your Jeep, ensuring a high-quality finish.

Pro Tips for a Superior Jeep Polish

Achieving a professional-grade polish on your Jeep requires some insider knowledge. One vital tip is to always work in a shaded area or indoors to prevent the polish from drying out too quickly in the sun, which can lead to uneven results. Another tip is to periodically mist the surface with a water spray. This helps in keeping the pad lubricated and reduces the chances of paint damage from overheating. When working on curved or hard-to-reach areas, opt for smaller pads to maintain control and ensure even application. For a deeper shine, consider applying multiple layers of polish, allowing each layer to properly set before applying the next. Lastly, always finish with a fine polish or a glaze to bring out the deepest luster and shine on your Jeep’s paintwork. These pro tips can elevate your polishing game, resulting in a finish that rivals professional detailing jobs.

Maintaining Your Jeep’s Shine Post-Polishing

Once your Jeep gleams with a fresh polish, preserving its shine is key. Regularly washing it with a mild, pH-neutral car soap and a soft mitt is essential to prevent surface scratches. Steer clear of automatic car washes, as their abrasive brushes can mar the polished finish. After each wash, gently dry the Jeep with a clean microfiber towel to avoid leaving water spots. Applying a premium wax or sealant is vital for protecting the polished surface. These items form a protective shield against ultraviolet radiation, grime, and contaminants from the surroundings. Regularly reapply the wax or sealant every few months to maintain a constant layer of protection. Parking in sheltered areas, like garages or under covers, can also help safeguard the paint from weather-related damage, keeping your Jeep looking pristine and well-maintained.

Conclusion

Concluding, the journey of polishing your Jeep with a drill is a rewarding endeavor that not only enhances the vehicle’s aesthetic appeal but also contributes to its long-term preservation. This guide has walked you through each critical step, from selecting the right tools and preparing the surface to the actual polishing process and post-polishing maintenance. The key takeaways include the importance of choosing suitable attachments, the need for a methodical approach during polishing, and the significance of maintaining the shine to prolong the effects of your hard work. Regular upkeep, combined with the right techniques, will ensure that your Jeep continues to turn heads with its gleaming finish. Remember, the art of drill polishing is as much about patience and attention to detail as it is about using the right tools. With practice and dedication, you’ll find that achieving a professional-level polish on your Jeep is an entirely attainable and satisfying goal.

Add Comment