Knowing how to troubleshoot a faulty speed sensor is essential if you own a Jeep. Speed sensors are important components in your vehicle’s engine that help regulate the speed of your car and keep it running smoothly. You may experience rough idling, poor acceleration, and other issues when they fail. In this article, we will discuss what a speed sensor is, the common symptoms of one that has failed, and how to diagnose and resolve an issue with a faulty speed sensor in your Jeep.

What Is a Speed Sensor?

A speed sensor is used on vehicles to measure the rotational speed of the driveshaft or wheel. It is typically found in automatic transmission systems, and it has two main functions: to measure the rate at which the wheels are spinning and to detect when the engine is running too fast. The speed sensor sends this information to the engine control unit (ECU), which then uses it to adjust various aspects of engine operation, such as fuel delivery and ignition timing. Without a working speed sensor, your Jeep won’t be able to regulate its performance and may experience issues with acceleration, idle speed, or even stalling out completely.

Symptoms of a Faulty Speed Sensor

There are several common symptoms that can alert you to potential issues with your vehicle’s speed sensor:

Gear Slippage: Speed sensors are important in regulating power transmission from the engine to the wheels. If your speed sensor malfunctions, it can cause slippage or delay when shifting gears. You may also notice jerking or clunking sounds when shifting gears.

- Check Engine Light: If your speed sensor has failed, the check engine light will likely come on, and you will need to diagnose the problem with an OBD scanner before fixing it.

- Unusual Noises: A damaged or malfunctioning speed sensor can also cause strange noises underneath your hood, such as rattling and clicking when accelerating or decelerating.

- Poor Fuel Economy: Faulty vehicle sensors can lead to poor fuel economy resulting in higher gas bills over time due to the inefficient fuel burning by your engine because it is not receiving accurate information about its current speed from the defective component.

- Erratic Speedometer Readings: One of the most obvious signs that something is wrong with your car’s speed sensor is erratic readings on its speedometer which could indicate either incorrect wheel rotation speeds or inaccurate vehicle acceleration data being sent by the failing component to other parts of your vehicle’s electrical system such as its engine control unit.

How to Test the Speed Sensor

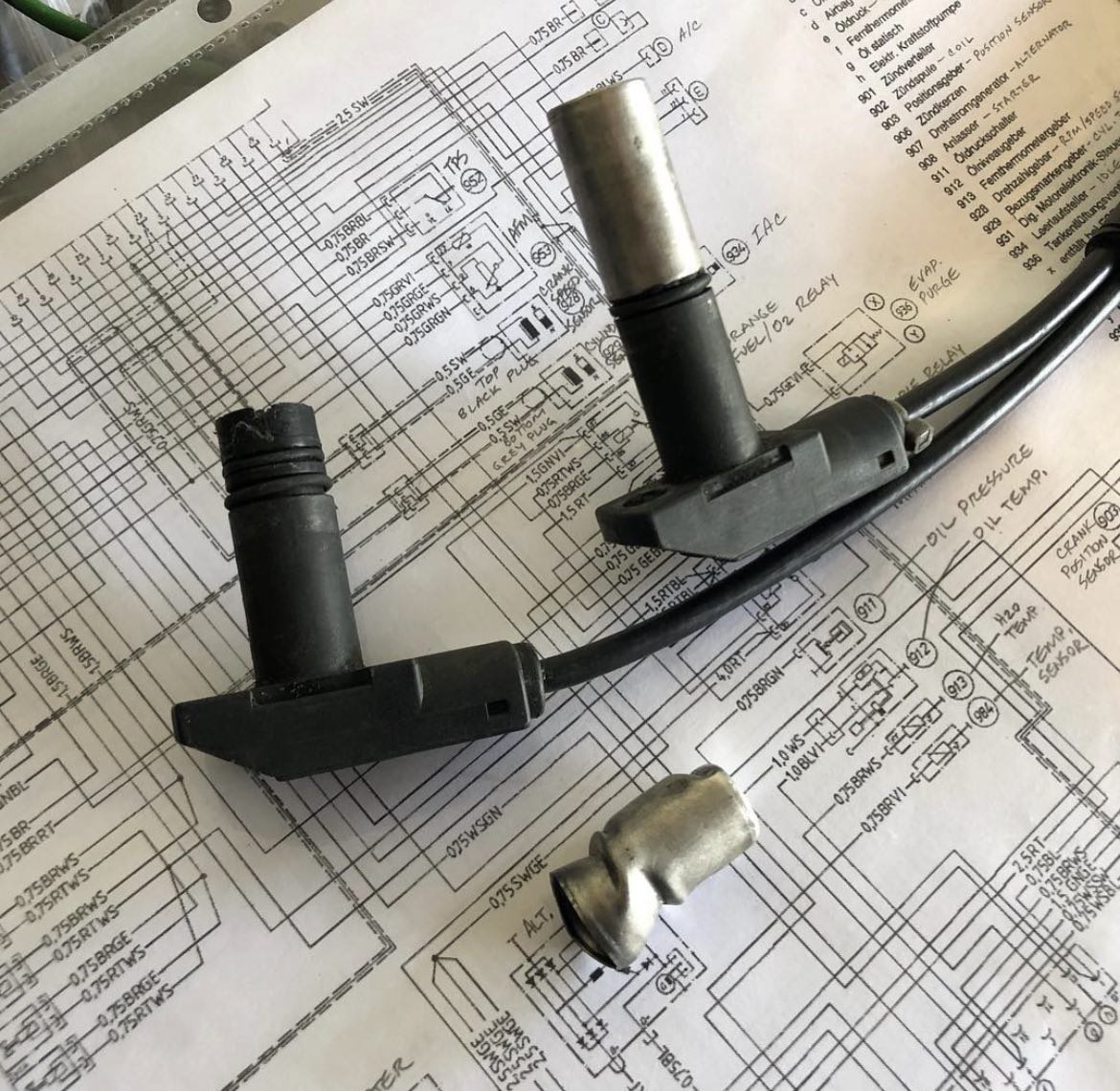

Before replacing the speed sensor, it must be tested to ensure it is malfunctioning. To do this, you will need a digital multimeter and some basic electrical tools such as wire cutters and strippers.

- Start by disconnecting the negative battery cable from your car’s battery. It will ensure that no electricity flows through the system while you are working on it.

- Locate the speed sensor in your vehicle’s engine compartment and unplug its electrical connector.

- Use a digital multimeter to measure the sensor’s resistance using its ohmmeter setting. An ideal reading should be between 50-200 ohms for most vehicles, so if yours reads outside of this range, there may be an issue with your speed sensor.

- If the resistance reading is too low or too high, the sensor may need to be replaced. If it is within the appropriate range, you must test it further using a scan tool or code reader to read any trouble codes stored in your car’s computer. It can help you determine if there is an issue with the wiring or other components in your car’s electrical system.

Replacing the Speed Sensor

When replacing the speed sensor, the first step is to locate its position within the vehicle, which can be situated in different locations depending on the make and model. Once found, the sensor is typically held in place by bolts or clips, which need to be carefully removed. It’s also important to disconnect any electrical connectors attached to the sensor. After the old sensor is removed, the new sensor can be installed, securing it with the appropriate fasteners and ensuring proper connection of electrical components. Finally, the vehicle’s computer system may need to be reset to recognize the new sensor and calibrate it accurately.

Conclusion

Troubleshooting a faulty speed sensor in your Jeep can be tricky, but with the right tools and knowledge, diagnosing and resolving any issues may have been possible. Always start by testing the sensor with a multimeter before replacing it, as this will help you determine if there is an issue with the wiring or other components in your car’s electrical system. Once you have decided that a new speed sensor is needed, install it correctly and reconnect all wires before turning on your car’s ignition to test if it works correctly.

Gear Slippage: Speed sensors are important in regulating power transmission from the engine to the wheels. If your speed sensor malfunctions, it can cause slippage or delay when shifting gears. You may also notice jerking or clunking sounds when shifting gears.

Gear Slippage: Speed sensors are important in regulating power transmission from the engine to the wheels. If your speed sensor malfunctions, it can cause slippage or delay when shifting gears. You may also notice jerking or clunking sounds when shifting gears.

Add Comment