Tightening your spark plugs properly is an important step in ensuring that your engine runs efficiently and stays in good condition. While it’s tempting to just crank the spark plug down as hard as you can, there are specific steps you should take to do it correctly. This guide will explain what tools and supplies you need, how to properly install your spark plugs, and what torque settings to use for different types of vehicles.

Tools and Supplies Needed for Spark Plug Installation

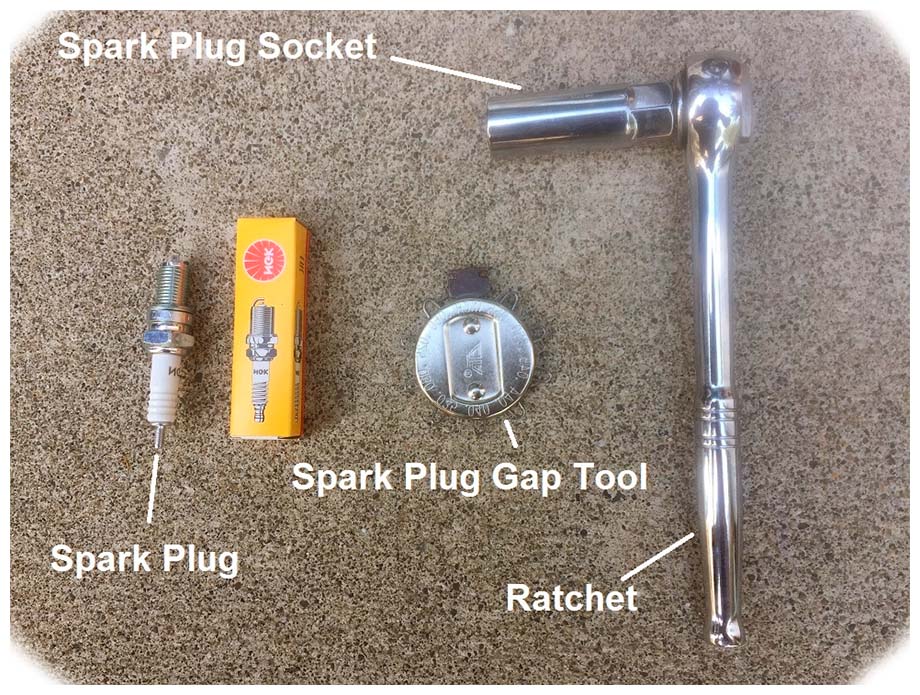

Before you can properly tighten your spark plugs, there are a few things you’ll need:

-

Spark plug wrench – A specialized tool that fits over the head of the spark plug and allows you to turn it without damaging the threads.

-

Socket – A socket is needed if your vehicle requires a special type of spark plug.

-

Anti-seize compound – This compound helps prevent corrosion on metal parts by providing a slippery coating. It also helps lubricate the threads so that they don’t get damaged when tightening or loosening the spark plugs.

-

Gap gauge – This tool is used to check the gap between the electrodes on each side of the plug is correct for your vehicle’s engine.

The Right Process for Installing Spark Plugs

Once you have all the necessary tools and supplies, it’s time to start installing your spark plugs. Here are the steps:

-

Make sure the engine is cool before you begin working on it.

-

Remove the old spark plug using your spark plug wrench or socket, whichever applies to your vehicle type.

-

Inspect the threads to make sure there is no corrosion or damage present that could prevent a proper seal between the plug and cylinder head. If there is damage, replace the cylinder head or have a professional do it for you.

-

Clean any debris from around the threading on both sides of the spark plug and apply anti-seize compound to protect against corrosion and lubricate threads before installation of new plugs to ensure a tight fit without cross threading or over-tightening of plugs upon installation on jeep vehicles

-

Use a gap gauge to measure and set the gap between electrodes on each side of the plug according to manufacturer specifications for your vehicle type.

-

Carefully install new spark plugs into cylinder heads snugly but not overly tight just until they are seated fully in cylinder heads.

Torque Settings for Different Vehicle Types

The torque settings for spark plugs will vary depending on the type of vehicle you’re working on. In general, the following values should be used when tightening spark plugs:

- Light-duty vehicles – 10 to 15 ft-lbs

- Medium-duty vehicles – 15 to 20 ft-lbs

- Heavy-duty vehicles – 25 to 35 ft-lbs.

It’s important to note that these values may vary depending on the vehicle, so always ensure to check the manufacturer’s recommended settings before you begin.

What Happens When You Over-tighten Your Spark Plugs?

Conclusion

Tightening spark plugs correctly in your Jeep is an important step in making sure your engine runs efficiently and stays in good condition. Be sure to follow the steps outlined above and use the correct torque settings for your vehicle type to ensure that your spark plugs are properly tightened without causing any damage. By following these simple steps, you can help keep your engine running smoothly for many years to come.

Spark plug wrench – A specialized tool that fits over the head of the spark plug and allows you to turn it without damaging the threads.

Spark plug wrench – A specialized tool that fits over the head of the spark plug and allows you to turn it without damaging the threads.

Add Comment