A properly functioning vehicle is essential for safe and comfortable travel, and one of the key components of any car is its idler pulley. The idler pulley helps drive accessories like power steering systems, air conditioners, alternators, and water pumps. If the idler pulley fails or begins to malfunction, it can cause a range of problems for your vehicle – from poor performance to a complete breakdown. This article will provide an overview of troubleshooting and replacing a bad idler pulley on a Jeep, allowing you to keep your ride running smoothly with minimal effort. We’ll cover the common signs of wear and tear or issues with an idler pulley system, as well as how to identify which component needs to be replaced. Additionally, we’ll discuss the steps required to safely replace these parts on Jeeps so you can enjoy carefree drives without worry.

Symptoms of a Bad Idler Pulley in Jeep

-

Squealing or squeaking noise when the engine is running: A damaged idler pulley can start to make loud squealing noises when the engine is running, usually due to an old or worn-out bearing.

-

Engine misfires: When the idler pulley becomes worn out or breaks, it could cause an interruption in power delivery, resulting in engine misfiring and stalling.

-

Check Engine Light: If any component near the idler pulley fails, such as a sensor that helps regulate air/fuel mixture, this could cause a Check Engine Light (CEL) warning signal on your dashboard.

-

Vibrations coming from under the hood: When there are problems with rotating parts like fan belts and idler pulleys, vibrations will become more pronounced and noticeable while driving at higher speeds or accelerating from idle speeds – this is because all these parts are connected by drive belts which rely on constant tension for reliability and smooth operation from your car’s engine components.

-

Difficulty starting the car: The idler pulley can cause problems in starting your vehicle, or it may not even start at all – this is because the idler pulley helps to keep tension on the belt. If it fails, the belt will be unable to turn other parts of the engine properly, leading to an inability to start your car.

If you have noticed any of the mentioned signs in your Jeep, it’s crucial to have it inspected by a certified mechanic immediately. Replacing a worn-out or faulty idler pulley before it fails can save you time and money in the long run.

Diagnosing the Problem

When diagnosing a bad idler pulley in your Jeep, it is important to identify the root cause of the problem. The first step is to check for broken or worn-out parts, such as belts, hoses, and pulleys. Additionally, look for any signs of oil or coolant leaks that may be related to a failing pulley system. If everything looks alright, you still hear strange noises from the engine compartment when driving at higher speeds or accelerating from idle speed – this could indicate a worn-out bearing in the idler pulley itself or other components connected by drive belts (alternator, power steering pump). To confirm whether the idler pulley is causing issues with your car’s performance, you can disconnect it and perform a visual inspection.

Tools Needed for Repairing the Idler Pulley

When it comes to replacing the idler pulley on your Jeep, there are a few tools and parts that you’ll need. First, have the correct replacement part for your car model and year. Next, gather the necessary tools: an adjustable wrench, socket set with an extension bar, ratchet set with appropriate size sockets/ratchets, flathead screwdriver (or similar device), hex key set (for removing bolts), and a torque wrench (for tightening bolts). Additionally, you may need a pry bar or panel remover to access some components – these will be necessary if you want to replace all related drive belt parts fully.

Step-by-step Guide to Replacing the Idler Pulley

After you’ve collected the required tools and materials, you can start changing the idler pulley.

-

First, raise your vehicle with a jack stand (or lift) and remove the wheel to access the engine compartment.

-

Loosen and remove the pulley bolts using a socket wrench set. If you have one, a belt tensioner tool can simplify this task.

-

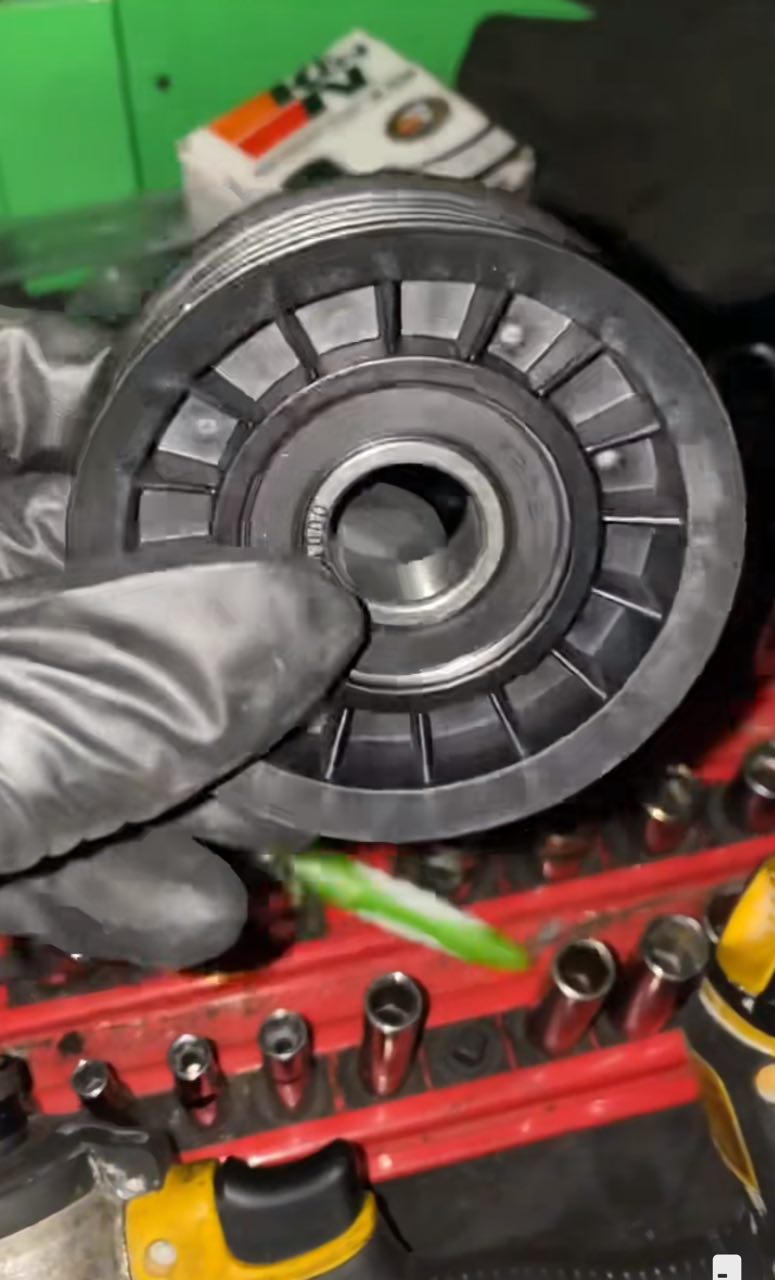

After removing all the bolts, gently detach the old idler pulley from its bracket and dispose of it.

-

Insert the new idler pulley into its mounting bracket – ensure it is properly aligned before tightening down any bolts or screws with pliers or a screwdriver.

-

Reinstall all your original bolts and screws that were holding your old idler pulley in place – you may need to apply some lubricant on them if they are old or rusted for them to come loose properly without damaging any parts of your Jeep engine compartment while doing so.

-

Finally, replace your wheel and lower your vehicle back onto all four wheels – this will ensure proper alignment for when you take it on a test drive after completing this repair job!

Conclusion

The idler pulley in a Jeep is an essential part of your vehicle’s belt system, and if it fails, you may experience a range of symptoms that can lead to further damage and expensive repairs. To avoid this, it is important to identify any possible signs of failure or wear and tear with your Jeep’s idler pulley system so that you can get it checked by a qualified mechanic as soon as possible. Additionally, the pulley needs to be replaced. In that case, this article provides step-by-step instructions on safely replacing the Jeep component and the tools needed for repairing it. With these simple instructions, you can keep your ride running smoothly with minimal effort!

Add Comment