Jeep vehicles are known for their power, reliability, and ruggedness. But even the best cars can suffer from mechanical issues that can be difficult to diagnose. If you’re experiencing problems with your Jeep vehicle, it could be a result of a loose flexplate. A flexplate is an integral part of a vehicle’s drivetrain, and if it is not working properly, it can cause significant problems for you and your Jeep. A problem with the flexplate can cause several symptoms that may vary depending on the model year and type of vehicle. In this article, we’ll discuss some common symptoms of a loose flexplate in Jeep vehicles, common causes, and how to fix them.

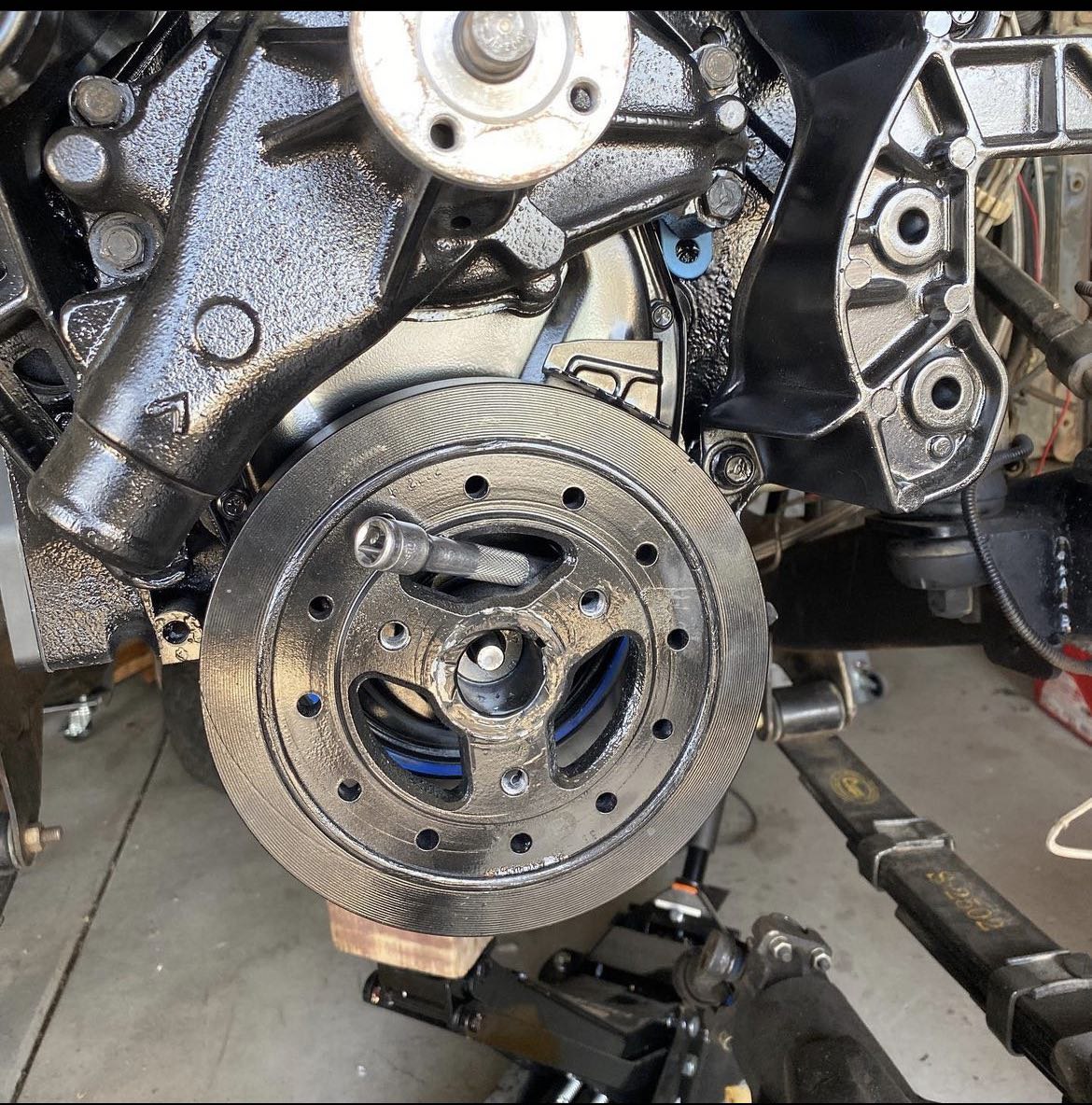

What Is a Flexplate?

The flexplate flexes and rotates as the engine rotates, enabling smooth power transfer to the transmission. The flexibility of the flexplate is essential as it helps absorb and dampen engine vibrations, reducing stress on the transmission and other drivetrain components. Overall, the flexplate is vital in ensuring a Jeep’s efficient and reliable operation equipped with an automatic transmission. Also read about Best Exhaust System for Jeep Wrangler.

Symptoms of a Loose Flexplate

A loose flexplate in Jeep vehicles can lead to noticeable symptoms that signal potential issues within the transmission system. One common indicator is an irregular rattling or knocking noise from the area around the transmission or engine when the vehicle is idling or in gear. This noise is often more pronounced during acceleration or when the engine is under load. Additionally, drivers might experience vibrations or shuddering sensations while driving, particularly during acceleration or deceleration. Gear shifting could become less smooth, with delays or jerky movements as the transmission struggles to engage correctly due to the compromised connection between the flexplate and torque converter. Monitoring these symptoms is crucial, as a loose flexplate affects the vehicle’s performance and drivability and can cause further damage to the transmission and surrounding components if left unaddressed.

Common Causes of a Loose Flexplate

A loose flexplate in a vehicle can lead to various performance issues and potential damage to the transmission system. Several common causes can contribute to a loose flexplate. One frequent cause is improper torque on the torque converter mounting bolts during installation. If these bolts are tightened to the manufacturer’s specifications, the flexplate may stay tight over time due to the constant rotation and vibration of the engine. Another factor can be worn or damaged flexplate bolts, which may fail to keep the flexplate securely attached to the torque converter or the crankshaft.

Additionally, engine misalignment or imbalance can lead to uneven stress on the flexplate, causing it to become loose. Regular wear and tear and heat cycles can also contribute to the deterioration of the flexplate’s mounting holes and overall structural integrity, resulting in a loose flexplate. Detecting and addressing these issues early is crucial to prevent further damage and maintain the proper function of the transmission system.

How to Fix a Loose Flexplate on Your Vehicle

Fixing a loose flexplate in your Jeep vehicle requires careful assessment and specific steps to address the issue properly. Begin by disconnecting the battery and removing any components blocking access to the flexplate, such as the air intake tube, engine cover, starter motor, torque converter, and transmission-to-engine mounting bolts. Then inspect the bolt pattern around the perimeter of the flexplate for any signs of wear or damage. Any missing or damaged bolts should be replaced with new ones of similar size and strength. Once all components are removed from the assembly, use a torque wrench to tighten all screws and bolts to manufacturer specifications. Finally, reinstall all parts in their original positions and reconnect the battery before starting up your Jeep vehicle. If done correctly, this should address your loose flexplate symptoms and help restore your Jeep’s performance back to normal.

Conclusion

A loose flexplate in a Jeep vehicle can lead to various symptoms that can affect its performance and drivability if left unaddressed. Knowing what symptoms can signal a problem with your flexplate is essential in detecting issues early on before they cause further damage within your drivetrain system. Common causes of a loose flexplate include improper installation or worn components, leading to uneven stress on its structure over time due to engine vibrations during operation. Fortunately, fixing this issue is relatively straightforward as long as you follow proper procedures when replacing faulty or worn-out parts while ensuring tight connections during reassembly. With proper maintenance attention paid towards diagnosing issues concerning your Jeeps’ drivetrain system, you’ll enjoy smooth operation for years!

Add Comment